Services

- Home

- /

- Services

Tank Refurbishment

At Clayex Technologies, we deliver expert corrosion protection and tank coating solutions, ensuring your tanks withstand the test of time and harsh conditions. Our thorough assessment and advanced surface preparation techniques lay the groundwork for applying superior coatings, tailored to meet the unique demands of your operations. These protective measures not only restore your tanks but also significantly enhance their resistance to corrosion and chemical damage.

Our dedicated approach guarantees a boost in your tanks’ longevity and performance, safeguarding your investment and operations. Trust in Clayex Technologies for robust corrosion treatment and coating services that promise to extend the life of your tanks and maintain their integrity against future challenges.

Comprehensive Industrial Tank Coating & Storage Tank Repair Services in Malaysia

Clayex Technologies is an organization that deals with the provision of quality industrial tank coating and storage tank repair. Being a quality conscious company, we ensure that your tanks are not only repaired but also fortified to withstand the most demanding conditions.

Additionally, we provide the facility for punching, combi (laser cut + punching), laser cut, bending, shearing, and rolling. These services are meant to improve on the performance of your storage tanks, increase their durability and meet recommended standards.

Clayex Technologies has always been passionate about the quality of its products, hence we guarantee our products to be very reliable and durable and has been in this business for several years. Accessibility to outstanding amenities and personnel means every work is done with accuracy and attention so that you can request services without stress.

Wish to get your industrial tank coating and storage tank repair done? Contact Clayex Technologies now. Quality, safety and environmental considerations are paramount to us and are reflected in all projects that we engage in.

Other Services

Punching

Punching in engineering refers to a manufacturing process where a tool called a punch is used to forcefully create holes or shapes in a material, typically metal. Punching is often the cheapest method for creating holes in sheet materials in medium to high production volumes. When a specially shaped punch is used to create multiple usable parts from a sheet of material (i.e. the punched-out piece is the good piece), the process is known as blanking. In metal forging applications the work is often punched while hot, and this is called hot punching. Slugging is a type of metal-punching operation in which the action of the punch is stopped as soon as metal fracture is complete; the punched piece is not removed but is left in the hole.

Combi

(Laser Cut + Punching)

Laser/high-speed turret punch Laser, and a tool station turret punch, we can process features such as louvers, lances, up forming, and tapping of holes. Multi-tier material stacking tower allows us to run various materials/jobs to maximize production and decrease lead times. With features such as self-loading and unloading, parts picking and sorting, we can run lights out 24/7 manufacturing. Laser cutting/punching materials with a thickness from .015” to .180” thick allow us to cover all your sheet metal needs.

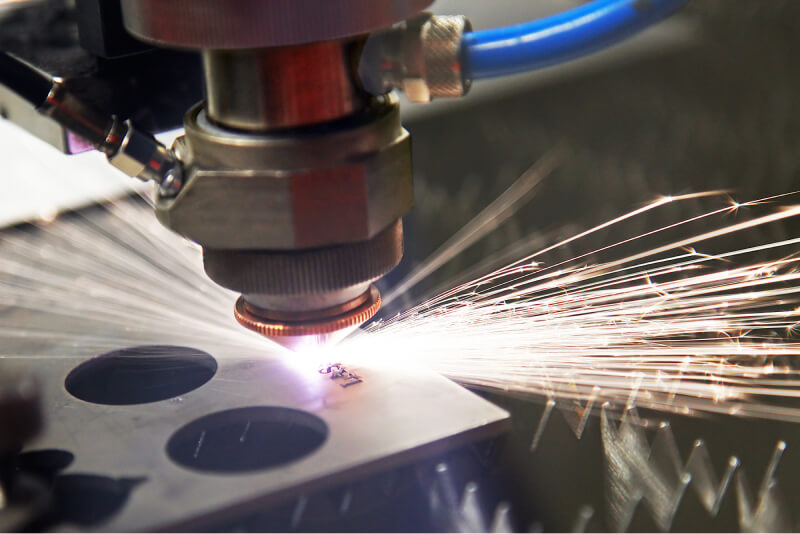

Laser Cut

Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the laser beam to the material. A commercial laser for cutting materials uses a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish.

Bending

Bending is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in ductile materials, most commonly sheet metal. Required radious as per request 90 degrees.

Shearing

Shearing involves the cutting of sheet and plate with high precision. Shears have a top and bottom blade and this process is very similar to cutting a piece of paper with scissors. Shears use blades made of high-carbon steel, which is extremely hard and allows the shear to cut through a variety of metals. Shearing is a standard service offered by Metal Supermarkets.

Rolling

Rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. Rolling is classified according to the temperature of the metal rolled.